TLDR: Henry Ford popularised the linear manufacturing production line for efficient, high-volume outputs, ideal for standardised products. In contrast, cell manufacturing has evolved through organisations such as Toyota and BMW and is characterised by self-contained manufacturing units that provide flexibility and responsiveness to market changes. These cells then feed into final assemblies for completion. In the world of bidding and proposals, the concept of relay bidding mirrors the production line approach, using linear and structured processes for high-volume, standardised proposal outputs. For more nuanced and complex bids, a more holistic approach to bidding is needed that closely mirrors the approach to cell manufacturing. This helps in utilising a highly-skilled, flexible, and collaborative bid team that generates better Buyer aligned bid responses, which are more cohesive and typically feature higher levels of innovation. There are benefits and downsides to each approach though. In determining the optimal approach, we propose that organisations should assess their own bidding strategy through a Decision Framework, considering output characteristics, production volume, process flexibility, cost-benefit, and risks. Supported by continuous improvements and strategic reviews, this helps organisations maintain relevance and competitiveness over time through evolving practices.

In search of bidding excellence

Learning from the motor industry

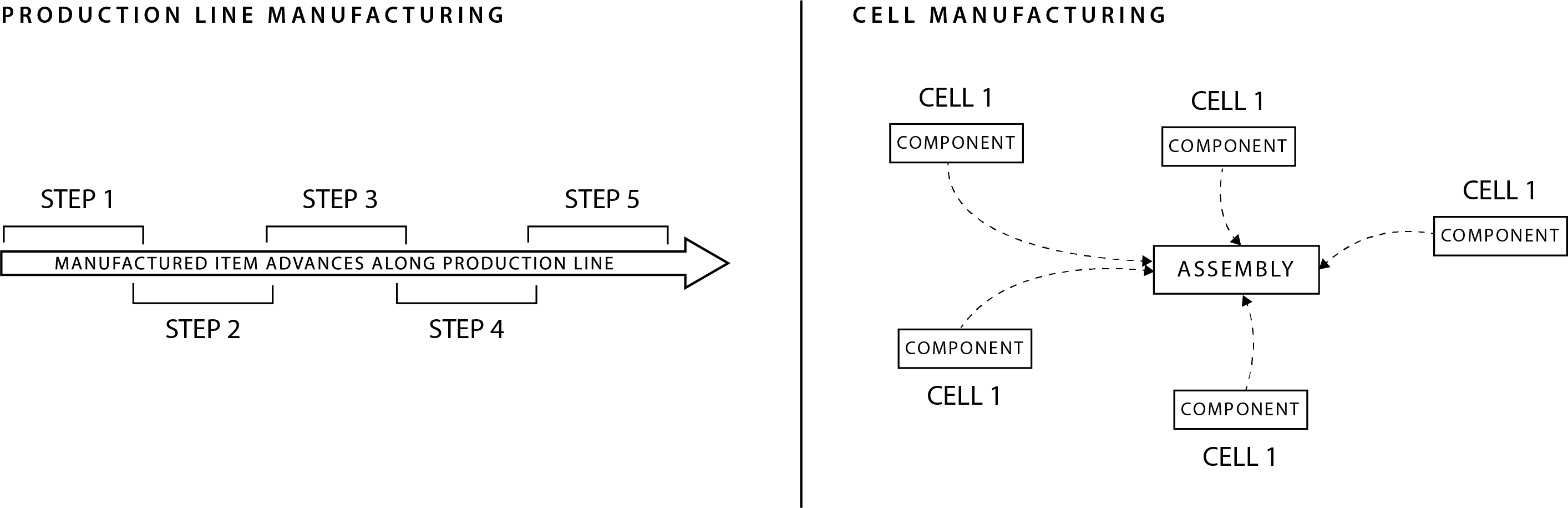

In manufacturing, production line manufacturing and cell manufacturing represent two distinct approaches to organising processes and outputs. Thanks to Henry Ford, many of us are familiar with production line manufacturing, which arranges workstations in a linear fashion, with each station specialising in a specific additive task or operation. This approach promotes high levels of specialisation and standardisation, leading to the efficient production of high volumes of repetitive products and or outputs.

In contrast to this, cell manufacturing divides the production process into self-contained units or cells, each responsible for producing a complete part or product group. Manufacturing cells are equipped with all necessary resources, skillsets, and help to promote flexibility and agility in responding to changes in demand or product specifications.

Figure 1: Overview of Production Line and Cell Approaches to Manufacturing

Ultimately, the choice between production line manufacturing and cell manufacturing depends on factors such as product complexity, demand variability, and desired levels of flexibility and efficiency. Generally, while production line manufacturing is well-suited for high-volume, standardised outputs, cell manufacturing offers greater flexibility and responsiveness to changing market demands and product variations.

In the world of automotive manufacturing, production line manufacturing has long been established as the overriding method of production. Henry Ford’s original production line approach for the Model T Ford standardised outputs helped to generate higher outputs and cheaper costs, establishing the Model T Ford as an affordable and durable vehicle that underpinned a growth in consumer demand and sparked the birth of the motor industry. With Ford’s approach came a rigid approach to production (available in any colour as long as it’s black) and an expensive system to adapt to accommodate trends, innovations, and competitive threats. Yet the manufacturing line approach persists due to its effectiveness, albeit with some adaptations for flexibility. Ford still embraces the approach today along with organisations such as Volkswagen, General Motors, and Honda.

In contrast, manufacturers such as Toyota and BMW have adopted a more cell-oriented process, with components constructed in small cells and brought together for final assembly. This allows for greater efficiency within each cell, facilitates different configurations of the final product to meet bespoke customer requirements, drives quality and innovation through the compartmentalisation of outputs, and enables greater flexibility of output by repurposing workforce and outputs to meet varying and emerging demands.

Each approach has merit and producers undertake a comprehensive analysis of factors in the form of a Manufacturing Decision Framework Assessment to determine an optimal approach. In broad terms though, production line outputs are seen as more rigid and suited for high volumes of same or similar outputs while cell outputs align more to customer demands, are flexible in terms of processes and outputs, and more responsive to market and competitor demands.

So why expand on motors and manufacturing when talking about bidding?

When undertaking bids, organisations typically align to production-line or cell approaches, or as we like to refer to them, relay bidding or holistic bidding.

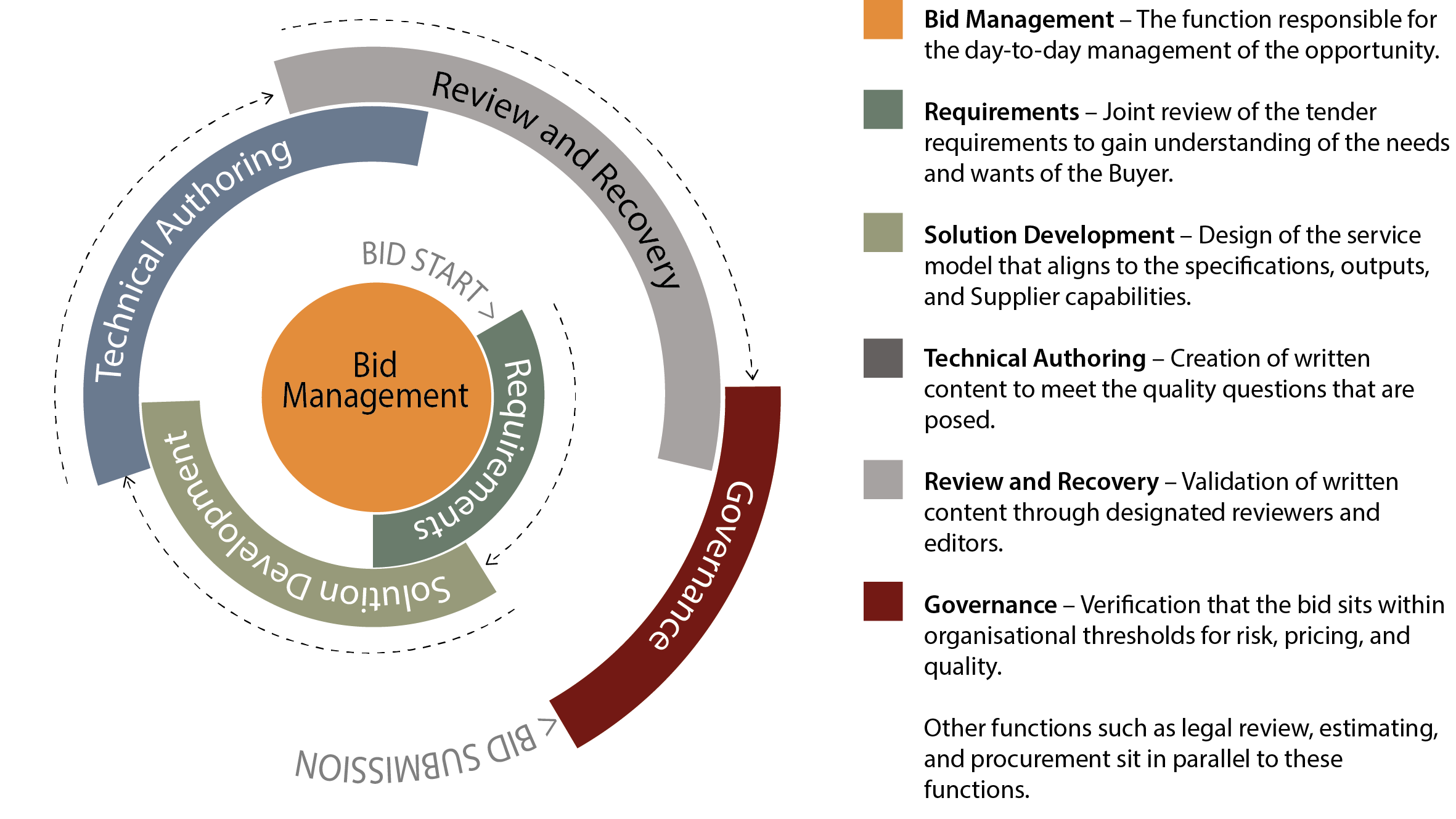

Under relay bidding (Figure 2), many attributes are shared with production line manufacturing in that each function tends to be distinct and linear in terms of progression e.g. the team spend time to understand the requirements, the solution is developed, responses are written, reviews are undertaken, and governance processes apply.

Relay bidding advances the bid through various stages with an element of certainty and generally facilitates a higher throughput of completed tenders. The approach also helps in recruiting employees with specific skill sets, supplementing the workforce with defined roles to meet team demands. This also aids in developing individuals along a structured career (and salary) progression route. Overall, it is an approach that works extremely well for transactional or commodity-based bidding where there is little variance or the need for a high volume of standard output – with bid teams working on several opportunities concurrently. Yet its strengths are also its biggest challenges.

Bids can appear as more generic in nature with outputs biased in favour of Supplier strengths. Development of the final bid is often repetitive and systematised, and employees tend to be skilled in specific areas of production such as writing, bid management, and solution development, making it harder to redeploy to other functions during downtime. Given that the approach drives concurrent working across multiple bids, it also leaves little time for members of the bid team to truly understand the ‘why’, ‘what’ and ‘how’ of the complete bid.

Figure 2: Overview of Relay Bidding and its Similarity to Production Line Manufacturing

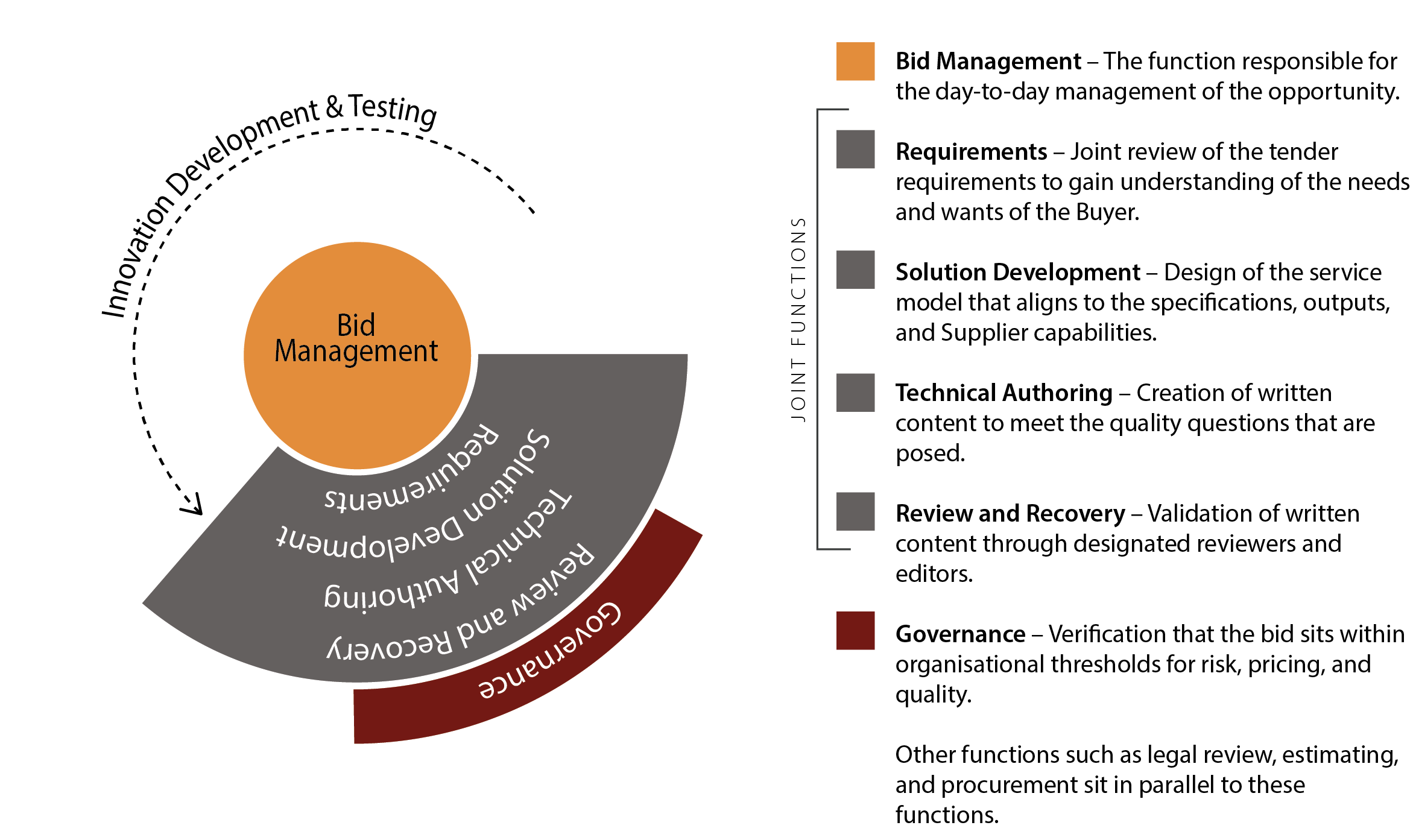

In contrast to relay bidding, holistic bidding aligns to the principles of cell manufacturing where a multi-skilled team focus on creating components of the bid with a view of the complete output (Figure 3).

Figure 3: Overview of Holistic Bidding and its Similarity to Cell Manufacturing

Bids that operate in this way can still build off of standard operational approaches and pre-existing bid collateral but focus more on generating a bespoke operating model and resultant response that is right-sized and aligns more to the Buyer requirements.

This holistic approach to bidding suits more technical proposal development where there are multiple inputs and specific drivers for success. Team members also tend to interact more, taking the time to comprehensively understand the requirements (the ‘why’, ‘what’ and ‘how’), to enable a higher level of customisation of the overall service model to suit the Buyer’s needs. There is also a greater appreciation of the interaction between the differing service areas that make up the overall service model, typically giving a more cohesive proposition that resonates more with Buyer, helps to remove 'siloed' solutioning, and largely removes the threat of margin-on-margin.

It can be said that the nature of holistic bidding also supports greater opportunities for innovation, with higher levels of interaction consistently between team members. This drives common problem-solving and aids in identifying areas where new approaches and ideas can produce competitive and operational advantages.

Holistic bids can be more resource intensive though, and with the multi-skilled capabilities of team members, can be more expensive to recruit roles for. This makes the approach more suited to complex and high-value bids where a significant degree of technical insight is needed to format the service model to align with Buyer needs, to drive innovation that helps reduce cost and improve quality, and to push a proposal ahead of the competition.

Determining the best approach for your organisation

Like manufacturing, bidding organisations should undertake a Decision Framework Assessment to inform ideal routes and structures for assembling bidding teams. This includes consideration of:

- Output Characteristics: Analysing the characteristics of the procurements to be bid, such as value, complexity, variability, and the need for customisation.

- Production Volume: Evaluating the expected production volumes for each procurement to determine the most suitable bidding approach.

- Process Flexibility: Assessing the level of flexibility required in the bid process to accommodate changes in Buyer requirements, varying timescales, competitor threats, or production volumes.

- Cost-Benefit Assessment: Conducting a comprehensive analysis of the costs and benefits associated with different bid production approaches, considering factors such as equipment costs, labour requirements, setup times, and operational expenses.

- Risk Assessment: Identifying and assessing potential risks and challenges associated with each bidding approach, including technology adoption risks, supply chain dependencies, staff burnout/retention, and market uncertainties.

- Decision Making and Strategy Selection: Based on the findings of the assessment and analysis, making informed decisions about the most suitable bidding approach for the organisation’s specific needs and objectives.

Your approach shouldn’t be static

Whatever approach is taken, it is worth acknowledging that circumstances change and that the right approach is iterative, not absolute. Beware though, frequent and significant changes to bid team configurations can be destabilising for the individuals affected by it, especially if the transformation is sudden and poorly managed.

In contrast, continuous evolution of the bid production approach can have a positive effect on the team and win rates, especially when individual members are involved with changes. This can be through ongoing improvement initiatives, team engagement, comprehensive outcome analyses, and/or investment in training and development. This not only ensures that the approach to bidding consistently aligns to market needs, but it also maintains relevance with Buyers’ needs over time.

How can the Keyne Group help your organisation?

Whatever approach your organisation has to bidding – either relay, holistic or a hybrid of the two – our teams have the industry experience to contribute meaningfully to every bid. Should you need to strategically review the structure and performance of your bid teams, or the processes and routines that they follow, we can help with this too. This includes:

- Carrying out a Decision Framework Assessment specifically for your organisation.

- Undertaking reviews and audits of previous bids and outcomes to determine potential improvement areas.

- Provide training and mentorship to bid teams on all aspects of bidding.

- Introduce continuous improvement frameworks that help to evolve the approaches to bids over time.

- Optimising bid team structure to align to organisational strategy and market demands.

Get in touch with us below to find out more.